| Doc No. |

SCC - FTU |

Rev. No. |

2 |

Date |

5 June 2020 |

A1. SCC FTU

Check boxes as follows: (✓) OK NI : Need Improvement (Pls. give comments at 'Remark' column)

| No. |

Description |

OK |

NI |

| 1. |

Visual Checks on FTU Cabinet |

| i. |

FTU cabinet is properly mounted & aligned at the wall / designated area. |

✓ |

|

|

| ii. |

QR code / label is available inside FTU Cabinet. Scan QR code and check contact (must be as per requirement in SOW).

[* If available for this contract]

|

✓ |

|

|

| iii. |

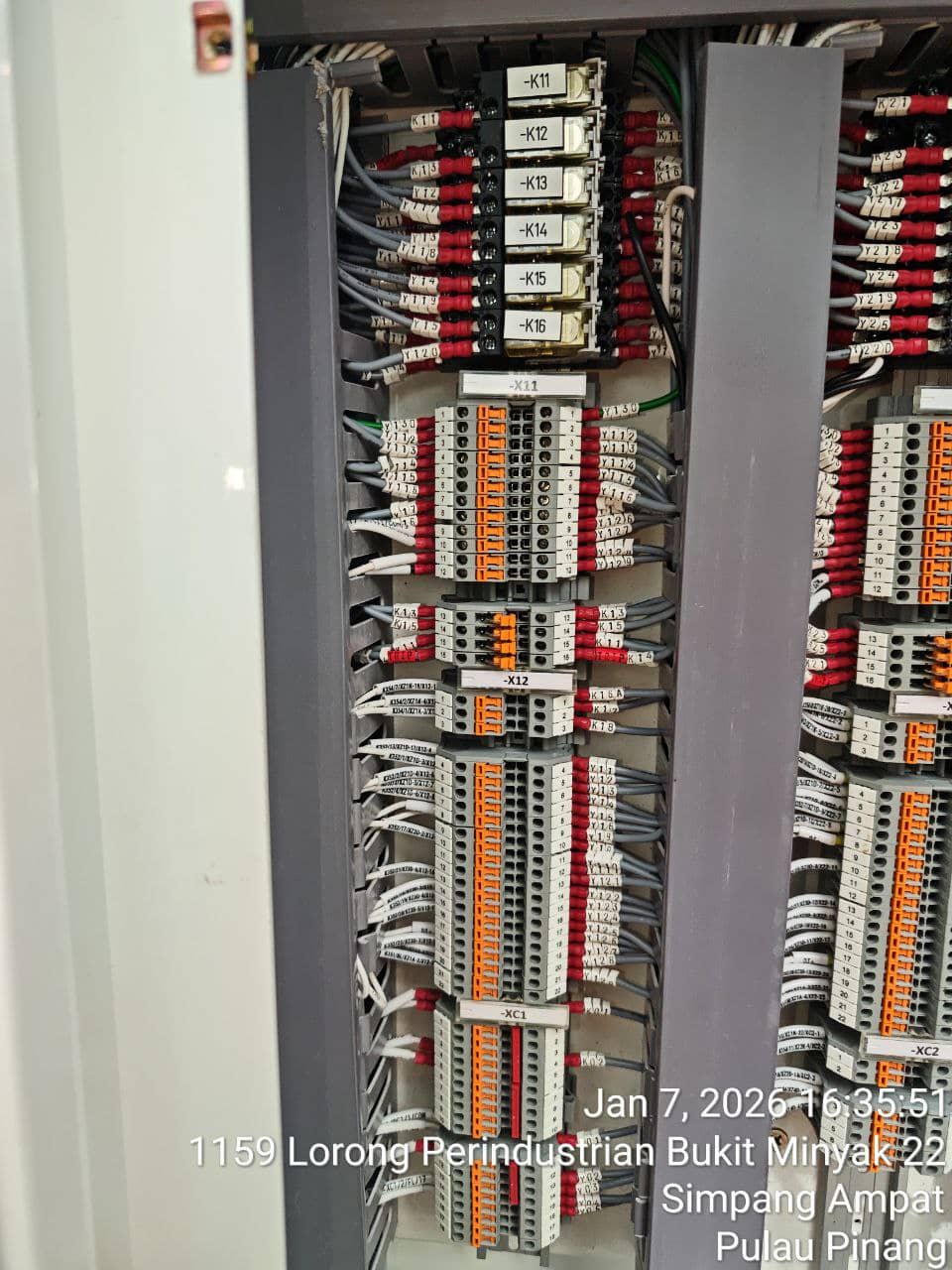

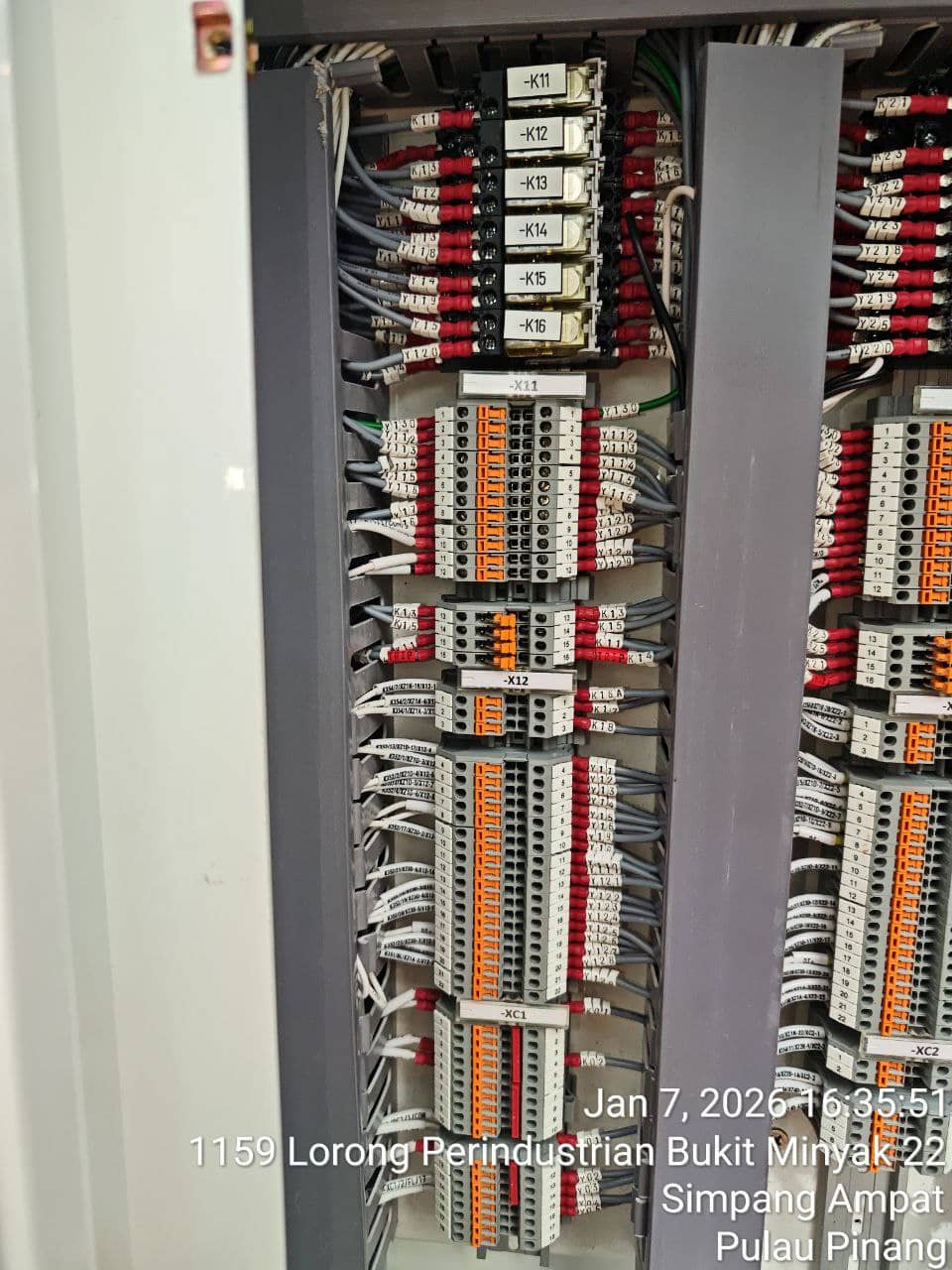

All wirings to the terminal blocks are terminated tightly and terminal blocks are in good condition. |

✓ |

|

|

| iv. |

All cable glands/ adaptors at both FTU and EFIs are installed properly. The cables shall be properly glanded at the cable entry points using proper glanding and sealing (to ensure no space/gap between the cable entry points and the panel)

|

✓ |

|

|

| v. |

Nameplate/Sticker with information on Serial Number, Site Acceptance Test (SAT) date & Warranty period is available in cabinet.

|

✓ |

|

|

| vi. |

SAT date must be written clearly & in the correct text position on the Nameplate/Sticker.

|

✓ |

|

|

| 2. |

Visual and Physical Checks on Cablings and Terminations |

| i. |

All non-armoured cables (including EFI CT cable) shall be installed in rigid high impact PVC conduits, neatly secured in position and adequately supported where necessary in an approved manner.

|

✓ |

|

|

| ii. |

The size of the PVC conduit shall be 25 mm in diameter and the colour of the conduit and fittings shall be orange. The conduits shall be fixed by means of saddles secured rigidly at intervals not exceeding 750 mm.

|

✓ |

|

|

| iii. |

Cable supports/brackets/elbows shall be installed at intervals not greater than 1500 mm for vertical runs and not greater than 1000 mm for horizontal runs. The brackets shall be derusted, finished in a primer and coated with standard orange enamel. The brackets/elbows shall not be painted.

|

✓ |

|

|

| iv. |

For armoured cables, cable supports, elbows, cleats, trays shall be used. All materials must be of galvanised type (of at least 1.2 mm in thickness).

|

✓ |

|

|

| v. |

Continuity tests shall be carried out for each core including spare cores.

|

✓ |

|

|

|

Observations:

|

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: 08-12-2025 |

Date: |

| Doc No. |

SCC - FTU |

Rev. No. |

2 |

Date |

5 June 2020 |

A1. SCC FTU

Check boxes as follows: (✓) OK NI : Need Improvement (Pls. give comments at 'Remark' column)

| No. |

Description |

OK |

NI |

| 3. |

Visual Checks on Installations |

| a. |

FTU equipment |

| i. |

All cablings and internal wirings for FTU modules and accessories are

laid properly & neatly secured.

|

✓ |

|

|

| ii. |

All the I/O points (inclusive of spares and unused points) are wired

internally, configured and ready for terminations from Field Devices,

(complete with its terminal blocks/connectors/wires and all other

necessary accessories).

|

✓ |

|

|

| iii. |

All cables for I/O signal, AC & Earth are laid & terminated

according to FTU Technical Specification.

|

✓ |

|

|

| b. |

Earth Fault Indicators (EFIs) |

| i. |

Installed on a mounting board, at designated area with cable markings

for each EFI.

|

✓ |

|

|

| ii. |

Not more than 2 nos. of EFIs on the mounting board.

|

✓ |

|

|

| iii. |

Printed stencils (black text on white, with laminated tape) are

available for numbering on the mounting board.

|

✓ |

|

|

| iv. |

The EFI CT cables are laid and terminated from EFI to Switchgears

(at the back or under the Switchgears).

|

✓ |

|

|

| 4. |

Site Drawings & Tests |

| i. |

Hardcopy of Approved Drawings

- Documents are available & placed inside FTU cabinet.

[Note: Any changes to the drawings shall be updated in

softcopy and passed to TNB as As-built drawings.]

|

✓ |

|

|

| ii. |

Hardcopy of Mastersheet & Wiring List (Working Copies)

- Any changes shall be updated/written in the Mastersheet &

Wiring List & verified, signed and stamped by TNB supervisor /

representative

- Documents are available & placed inside the FTU cabinet.

|

✓ |

|

|

| iii. |

Check & verify all necessary tests (including cable continuity

tests for all cabling work) are performed as required & have passed.

|

✓ |

|

|

|

Observations:

|

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: 08-12-2025 |

Date: |

| Doc No. |

SCC - RTU (SAT) |

Rev. No. |

1 |

Date |

5 June 2020 |

Note: Please sketch the building layout and the location of:

a. RCB panel

b. Battery Charger

c. EFIs location

d. Switchgear Panel

e. RTU Panel

SITE DRAWING:

EFI

EFI

FEEDER

FEEDER

FEEDER

FTU

DB

DOOR

| Doc No. |

SAT TP-FTU |

Rev. No. |

2 |

Date |

28 February 2024 |

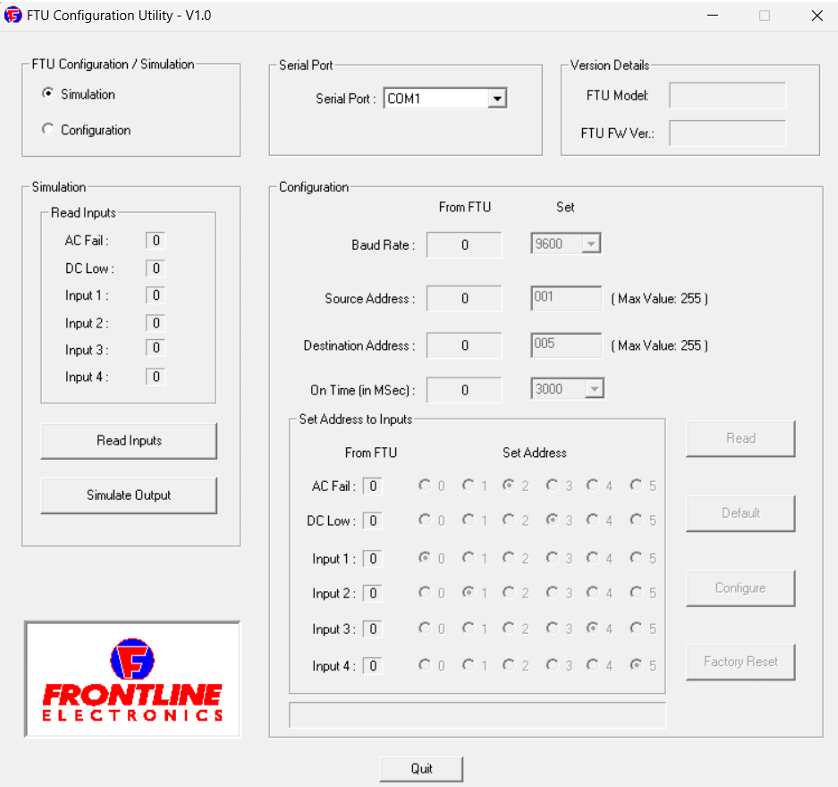

A1. FTU PARAMETER SETTING CHECK

| Test Ref: |

FTU Parameter Setting Check (Frontline Electronics)

|

| PC.1 |

| a) |

Site Acceptance Test List (FTU Parameter Setting Check) |

| No. |

Description |

YES |

NO |

| 1 |

Baudrate |

9600 |

✓ |

|

|

| 2 |

Source Address |

1 |

✓ |

|

|

| 3 |

Destination Address |

5 |

✓ |

|

|

| 4 |

Relay ON Time (ms) |

3000 |

✓ |

|

|

| 5 |

AC Fail Address |

2 |

✓ |

|

|

| 6 |

DC Low Address |

3 |

✓ |

|

|

| 7 |

Input 1 |

0 |

✓ |

|

|

| 8 |

Input 2 |

1 |

✓ |

|

|

| 9 |

Input 3 |

4 |

✓ |

|

|

| 10 |

Input 4 |

5 |

✓ |

|

|

| 11 |

FTU Model |

FE-TQ-FTU-022017 |

✓ |

|

|

| 12 |

FTU FW Version |

FTU-FW-002-2017 |

✓ |

|

|

|

Test Observations:

|

|

|

Test Result: PASS ☑ FAIL ☐

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: |

Date: |

| Doc No. |

SAT TP-FTU |

Rev. No. |

2 |

Date |

28 February 2024 |

A1. FTU PARAMETER SETTING CHECK

| Test Ref: |

FTU Parameter Setting Check (Frontline Electronics)

|

| PC.1 |

|

Test Observations:

|

|

|

Test Result: PASS ☑ FAIL ☐

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: |

Date: |

| Doc No. |

SAT TP-FTU |

Rev. No. |

2 |

Date |

28 February 2024 |

A2. FTU SYSTEM’S FUNCTIONAL CHECK

| Test Ref: |

FTU System’s Functional Check

|

| FC.1 |

| a) |

Site Acceptance Test List (FTU Parameter Setting Check) |

| No. |

Description |

Procedures and Criteria |

YES/NO |

| 1 |

RID Configuration check |

All configurations and settings are set accordingly. |

YES |

|

| 2 |

AC supply check at FTU |

Make sure MCB is ON and terminal shall has 240Vac. |

YES |

|

| 3 |

AC supply check at EFI |

Check the voltage source at EFI to be 240Vac. |

YES |

|

| 4 |

DC supply ON |

Check terminal MW +/- Bat. are: >12Vdc |

YES |

|

| 5 |

I/O cable EFI 1 |

Press the test button at the EFI1. A signal shall be picked up at the Protocol Analyser. |

YES |

|

| 6 |

I/O cable EFI 2 |

Press the test button at the EFI2. A signal shall be picked up at the Protocol Analyser. |

YES |

|

| 7 |

I/O cable EFI 3 |

Press the test button at the EFI3. A signal shall be picked up at the Protocol Analyser. |

|

|

| 8 |

I/O cable EFI 4 |

Press the test button at the EFI4. A signal shall be picked up at the Protocol Analyser. |

|

|

| 9 |

LED light ok |

LED is light ON. Switch it OFF before closing the panel and leaving the station. |

YES |

|

| 10 |

Test AC Fail Alarm |

Turn OFF the AC. Protocol Analyser shall pick-up the alarm. |

YES |

|

| 11 |

Test DC Low Alarm |

Use a cable to short the MW’s AC OK terminal. Protocol Analyser shall pick-up the alarm. |

YES |

|

| 12 |

Reset EFI 1 operate |

Use Protocol Analyser to simulate a reset signal. The EFI1 will start to flash (resetting). |

YES |

|

| 13 |

Reset EFI 2 operate |

Use Protocol Analyser to simulate a reset signal. The EFI2 will start to flash (resetting). |

YES |

|

| 14 |

Reset EFI 3 operate |

Use Protocol Analyser to simulate a reset signal. The EFI3 will start to flash (resetting). |

|

|

| 15 |

Reset EFI 4 operate |

Use Protocol Analyser to simulate a reset signal. The EFI4 will start to flash (resetting). |

|

|

|

Test Observations:

|

|

|

Test Result: PASS ☑ FAIL ☐

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: |

Date: |

| Doc No. |

SAT TP-FTU |

Rev. No. |

2 |

Date |

28 February 2024 |

A3. FTU MASTERSHEET RECORD

| Test Ref: |

Mastersheet Record

|

| MS.1 |

PROTOCOL IEC 101:

| No. |

Description |

Port Address |

IEC101 IOA |

IEC104 IOA |

Remarks |

| 1 |

EFI 1 status |

|

|

|

|

| 2 |

EFI 2 status |

|

|

|

|

| 3 |

EFI 3 status |

|

|

|

|

| 4 |

EFI 4 status |

|

|

|

|

| 5 |

Spare |

|

|

|

|

| 6 |

Spare |

|

|

|

|

| 7 |

AC Fail |

|

|

|

|

| 8 |

DC Low |

|

|

|

|

| 9 |

EFI Reset |

|

|

|

|

PROTOCOL DNP3:

| No. |

Description |

Port Address |

DNP3 IOA |

IEC104 IOA |

Remarks |

| 1 |

EFI 1 status |

|

0 |

|

DONE |

| 2 |

EFI 2 status |

|

1 |

|

DONE |

| 3 |

EFI 3 status |

|

4 |

|

DONE |

| 4 |

EFI 4 status |

|

5 |

|

DONE |

| 5 |

Spare |

|

- |

|

DONE |

| 6 |

Spare |

|

- |

|

DONE |

| 7 |

AC Fail |

|

2 |

|

DONE |

| 8 |

DC Low |

|

3 |

|

DONE |

| 9 |

EFI Reset |

|

0 |

|

DONE |

|

Test Observations:

|

|

|

Test Result: PASS ☑ FAIL ☐

|

Checks conducted by:

Contractor's Signature & Stamp:

|

Verified by:

TNB's Representative Signature & Stamp:

|

|

|

|

| Name: NAZRULL ZIQRAM |

Name:

|

| Date: |

Date: |